Fri, Jul 18, 2025

[Archive]

Volume 18, Issue 1 (March 2021)

IJMSE 2021, 18(1): 91-109 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Suresh Kumar C, Dhanaraj K, Vimalathithan R M, Ilaiyaraja P, Suresh G. Structural, Morphological and Anti-bacterial Analysis of Nanohydroxyapatite Derived from Biogenic (SHELL) and Chemical Source: Formation of Apatite. IJMSE 2021; 18 (1) :91-109

URL: http://ijmse.iust.ac.ir/article-1-1954-en.html

URL: http://ijmse.iust.ac.ir/article-1-1954-en.html

Chimmachandiran Suresh Kumar

, Kaliyan Dhanaraj

, Kaliyan Dhanaraj

, Ramasamy Mariappan Vimalathithan

, Ramasamy Mariappan Vimalathithan

, Perumal Ilaiyaraja

, Perumal Ilaiyaraja

, Govindhasamy Suresh

, Govindhasamy Suresh

, Kaliyan Dhanaraj

, Kaliyan Dhanaraj

, Ramasamy Mariappan Vimalathithan

, Ramasamy Mariappan Vimalathithan

, Perumal Ilaiyaraja

, Perumal Ilaiyaraja

, Govindhasamy Suresh

, Govindhasamy Suresh

Abstract: (16559 Views)

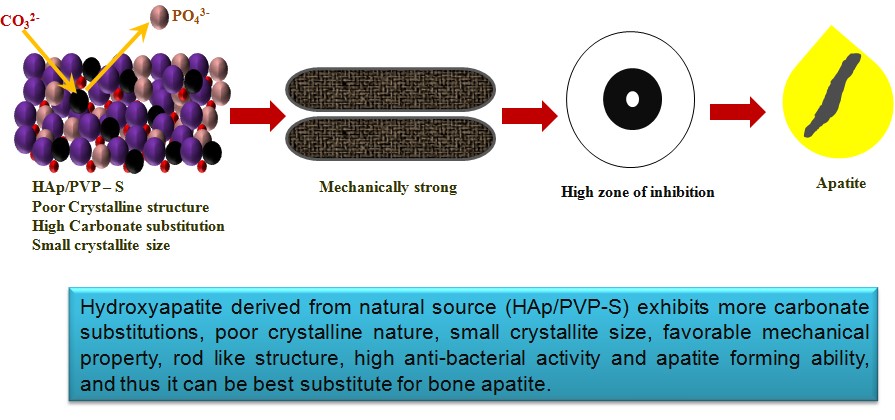

The Nano Hydroxyapatite (HAp), HAp/PEG and HAp/PVP powders derived from both Gastropod shell (natural source) and chemical precursor by the precipitation method were characterized through various characterization techniques such as FT-IR, XRD, SEM-EDX, TEM, Antibacterial activity and SBF analysis. Based on the structural, chemical, morphological and biological characteristics, HAp/PVP from natural and chemical precursors have been compared successfully. Calculated structural parameters, crystallinity index, C/P ratio, morphology, antibacterial activity and SBF analysis of the products show that HAp/PVP-S (derived from a natural source) exhibits good mechanical property, rod like morphology, good antibacterial activity and apatite formation ability at 14 days. EDX analysis also shows the presence of carbon and sodium in HAp/PVP-S. Comparative analysis reveals that characteristics of HAp/PVP-S such as high carbonate content, low crystallite size, poor crystalline nature, presence of trace metal, non-stoichiometric elemental composition and rod like crystals which are matched with the characteristics of biological apatite. Thus, the HAp/PVP-S has the ability to form bone apatite.

Keywords: Hydroxyapatite, Precipitation Method, Comparative Analysis, Antibacterial activity, SBF Analysis

Type of Study: Research Paper |

Subject:

Ceramic Materials and Engineering

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |