Volume 14, Issue 1 (March 2017)

Abstract

(26160 Views) |

Full-Text (PDF)

(6103 Downloads)

|

Graphical Abstract

|

Highlights

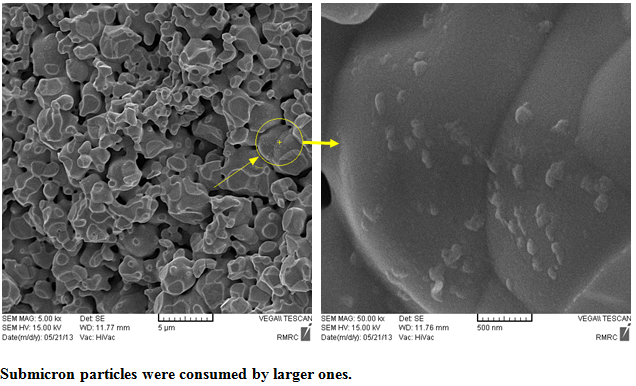

- Microstructure change during sintering of tungsten powders in presence of submicron particles.

- Decreasing sintering temperature of tungsten skeleton from 2200 to 1650oC.

- Fracture mode changing from inter-granular fracture interface fracture to trans-granular fracture due to submicron particles.

Abstract

(24907 Views) |

Full-Text (PDF)

(5648 Downloads)

|

Graphical Abstract

|

Highlights

- Microstructures of sintered ball-milled compacts showed homogeneous distribution of lead as compared to as-mixed 6061Al-Pb alloys.

- The 6061Al-Pb alloys produced using ball-milling route exhibits superior tribological properties than as-mixing processing route.

- The lowest wear rate was observed for as-mixed and ball-milled 6061Al alloy at 5 and 10 vol. % Pb, respectively.

- Ball-milled 6061Al-Pb alloy requires higher load for transition to severe wear regime than as-mixed 6061Al-Pb alloy.

Abstract

(27964 Views) |

Full-Text (PDF)

(5445 Downloads)

|

Graphical Abstract

|

Highlights

- Single phase zinc ferrite nanoparticles exhibited the partially inverse spinel structures.

- The band gap was related to the synthesis temperature via the crystallite size.

- Very small particle size lead to the less photocatalytic activity.

Abstract

(23061 Views) |

Full-Text (PDF)

(5905 Downloads)

|

Graphical Abstract

|

Highlights

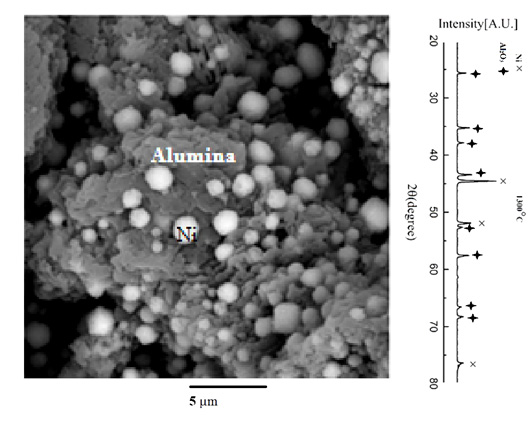

- Coprecipitation of aluminum and nickel hydroxides were done homogeneously at pH=8.8

- NiAl2O4 spinel were prepared from precipitated powders at 900 ̊C .

- Reduction of spinel to Al2O3-Ni composite were completed at 1300 ̊C .

- Particles of Ni uniformly distributed at Al2O3 matrix.

Abstract

(20276 Views) |

Full-Text (PDF)

(5749 Downloads)

Abstract

(24537 Views) |

Full-Text (PDF)

(6327 Downloads)

|

Graphical Abstract

|

Highlights

- Boronizing the surface of the tungsten heavy alloy to improve its surface hardening.

- Formation of tungsten boride (WB) as a very hard coating.

- Formation of nickel silicide phase as the outer layer over the boride layer.

- Tremendous improvement of surface hardening obtained after boronizing.

Abstract

(23318 Views) |

Full-Text (PDF)

(5664 Downloads)

|

Graphical Abstract

|

Highlights

- Cu,Ni, and Zn aluminate prepared by impregnation

- The non- porous CuAl2O4 obtained by impregnation method

- The specific surface area of nickel and zinc aluminates was in 47-87 m2/g

- The CuAl2O4 well crystallized and zinc and nickel aluminates had amorphous phase

- The nickel aluminates had lower acidity than zinc aluminates

Export as:

HTML

|

XML

|

RSS