Sat, Dec 14, 2024

[Archive]

Abstract: (1 Views)

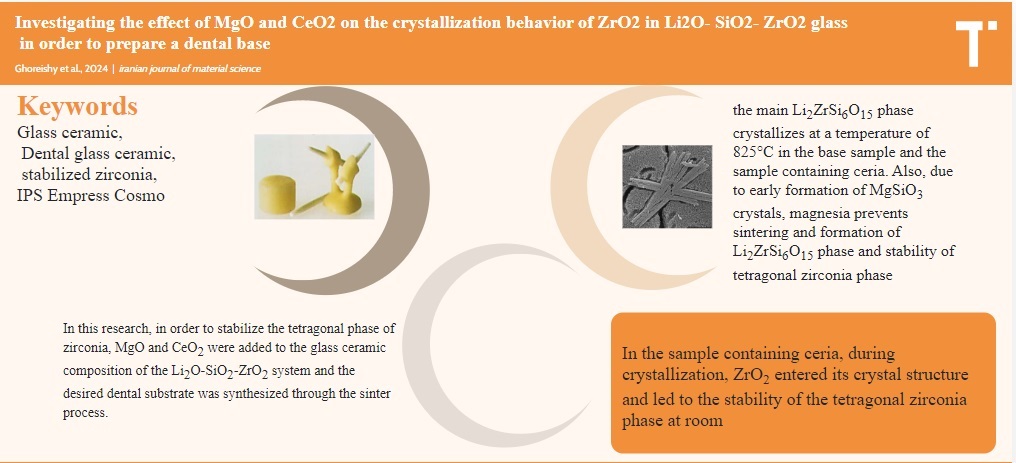

ZrO2 is commonly incorporated into ceramic glass substrates to enhance radiopacity, mechanical strength, and chemical durability. Experience has shown that the crystallization of tetragonal zirconia in glass will have a greater effect on the mechanical properties of ceramic glass. To achieve optimal properties in zirconia, stabilizing oxides are often added to enhance its structural and mechanical qualities. In this research, in order to stabilize the tetragonal phase of zirconia, MgO and CeO2 were added to the glass ceramic composition of the Li2O-SiO2-ZrO2 system and the desired dental substrate was synthesized through the sinter process. The behavior of sintering and crystallization of basic and optimized glass was investigated using HSM and DTA thermal analysis, respectively. The results showed that the optimal sinter temperature, heat press and heat treatment are equal to 730°C, 900°C and 825°C, respectively. Then, in order to determine the crystallization behavior of the prepared samples, X-ray diffraction and microstructure images were used. The results also showed that the presence of the main Li2ZrSi6O15 phase crystallizes at a temperature of 825°C in the base sample and the sample containing ceria. Also, due to early formation of MgSiO3 crystals, magnesia prevents sintering and formation of Li2ZrSi6O15 phase and stability of tetragonal zirconia phase. In the sample containing ceria, during crystallization, ZrO2 entered its crystal structure and led to the stability of the tetragonal zirconia phase at room temperature.

Type of Study: Research Paper |

Subject:

Synthesis and preparation of materials to meet the requirements of AM techniques

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |