Sun, Dec 15, 2024

[Archive]

Volume 21, Issue 3 (September 2024)

IJMSE 2024, 21(3): 1-10 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

A'yuni D Q, Hadiantono H, Velny V, Subagio A, Djaeni M, Mufti N. Efect of Potassium Hydroxide Concentration and Activation Time on Rice Husk-Activated Carbon for Water Vapor Adsorption. IJMSE 2024; 21 (3) :1-10

URL: http://ijmse.iust.ac.ir/article-1-3522-en.html

URL: http://ijmse.iust.ac.ir/article-1-3522-en.html

Dewi Qurrota A'yuni

, Hadiantono Hadiantono

, Hadiantono Hadiantono

, Velny Velny

, Velny Velny

, Agus Subagio

, Agus Subagio

, Moh. Djaeni

, Moh. Djaeni

, Nandang Mufti

, Nandang Mufti

, Hadiantono Hadiantono

, Hadiantono Hadiantono

, Velny Velny

, Velny Velny

, Agus Subagio

, Agus Subagio

, Moh. Djaeni

, Moh. Djaeni

, Nandang Mufti

, Nandang Mufti

Abstract: (8318 Views)

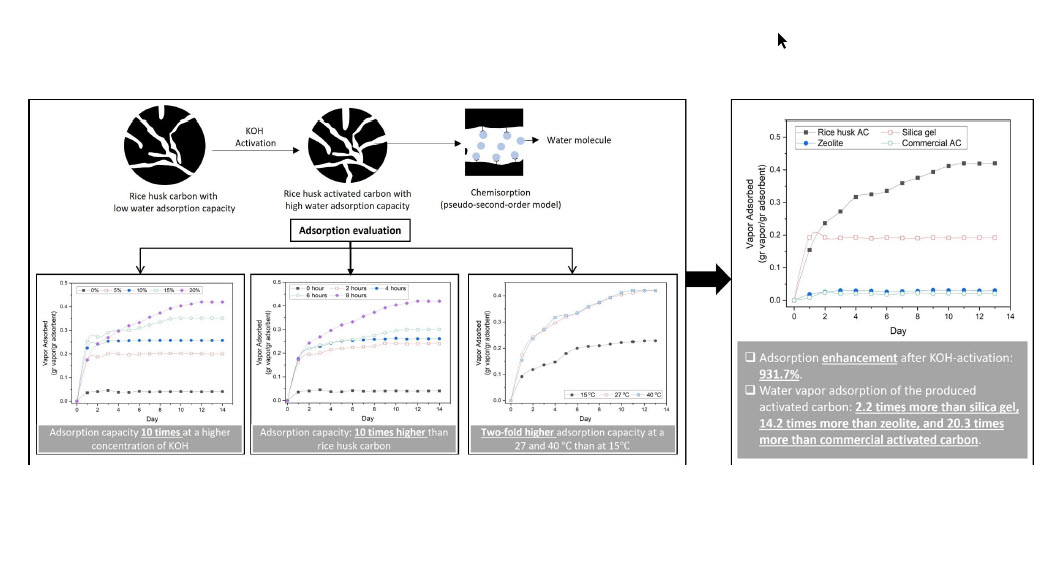

Rice husk carbon by-product from the industrial combustion is a promising source to produce a vast amount of activated carbon adsorbent. This research prepared rice husk-activated carbon adsorbent by varying the concentration of potassium hydroxide solution (5, 10, 15, 20 % w/v) and activation time (2, 4, 6, 8 hours). Fourier-transform infrared spectral characterization (FTIR) indicated a significant effect before and after activation, especially the presence of hydroxyl groups. Based on the iodine adsorption, the specific surface area of the produced-activated carbon was approximately 615 m2/g. Experimental results showed that increasing potassium hydroxide concentration and activation time increases the water vapor adsorption capacity of the activated carbon. Compared with the rice husk carbon, the KOH-activated carbon enhanced the water vapor adsorption capacity to 931%. In the adsorption observation, changing the temperature from 15 to 27 ℃ caused a higher water vapor uptake onto the activated carbon. Two adsorption kinetics (pseudo-first- and pseudo-second-order models) were used to evaluate the adsorption mechanism. This research found that rice husk-activated carbon performed a higher water vapor adsorption capacity than other adsorbents (silica gel, zeolite, and commercially activated carbon).

Type of Study: Research Paper |

Subject:

Other subjects

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |