Sat, Jul 19, 2025

[Archive]

Volume 21, Issue 2 (June 2024)

IJMSE 2024, 21(2): 77-88 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Dehghaniyan S F, Sharafi S. Synthesis and Characterization of Nanostructured (Fe80Ni20)1-xCrx(x= 0, 4) Alloys Using Mechanical Alloying and Density Functional Theory. IJMSE 2024; 21 (2) :77-88

URL: http://ijmse.iust.ac.ir/article-1-3433-en.html

URL: http://ijmse.iust.ac.ir/article-1-3433-en.html

Abstract: (12370 Views)

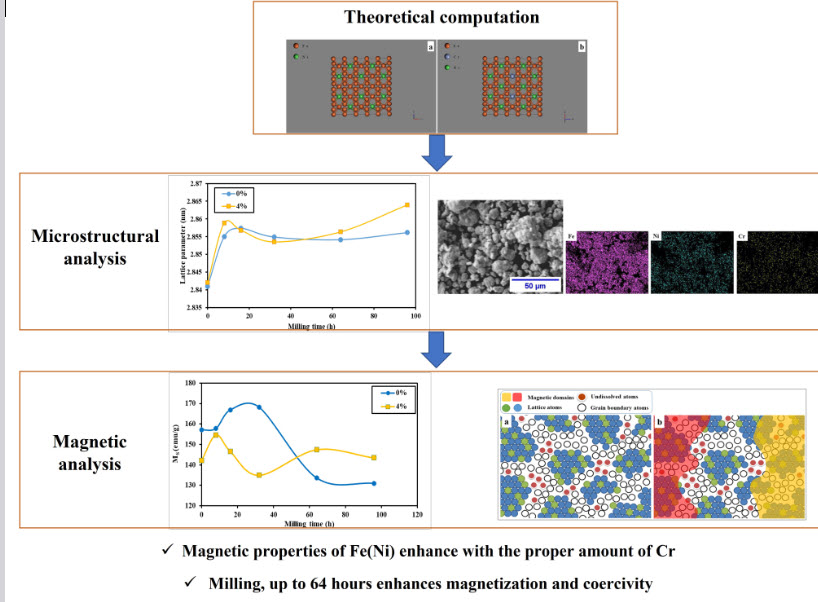

Mechanical alloying was employed to synthesize a nanostructured alloy with the chemical formula of (Fe80Ni20)1-xCrx (x= 0, 4). The microstructural and magnetic properties of the samples were investigated using scanning electron microscopy (SEM), X-ray diffraction (XRD), energy dispersive X-ray spectroscopy (EDS), and a vibrating sample magnetometer (VSM). Additionally, theoretical calculations were performed using density functional theory (DFT) under the generalized gradient approximation (GGA). Simulations have demonstrated that an appropriate quantity of chromium (Cr) can dissolve within the BCC-Fe (Ni) structure, resulting in a favorable enhancement of the magnetic moment of the lattice. The XRD results indicated that after 96 hours of milling, Fe (Ni) and Fe (Ni, Cr) with a body-centered cubic (BCC) structure were formed. With increasing milling time, the grain size decreased while the microstrain increased. The saturation magnetization (Ms) of Fe80Ni20 composition increased up to 32 hours of milling, but further milling (up to 96 h) resulted in a decrease in the saturation magnetization However, for the (Fe80Ni20)96Cr4 powders, milling up to 64 h caused a reduction in Ms. The coercivity (Hc) trend was different and increased with longer milling times (up to 96 h) for both compositions.

Keywords: Mechanical alloying, saturation magnetization, nanostructured alloy, density functional theory

Type of Study: Research Paper |

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |