Sun, Dec 15, 2024

[Archive]

Volume 20, Issue 2 (June 2023)

IJMSE 2023, 20(2): 1-11 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

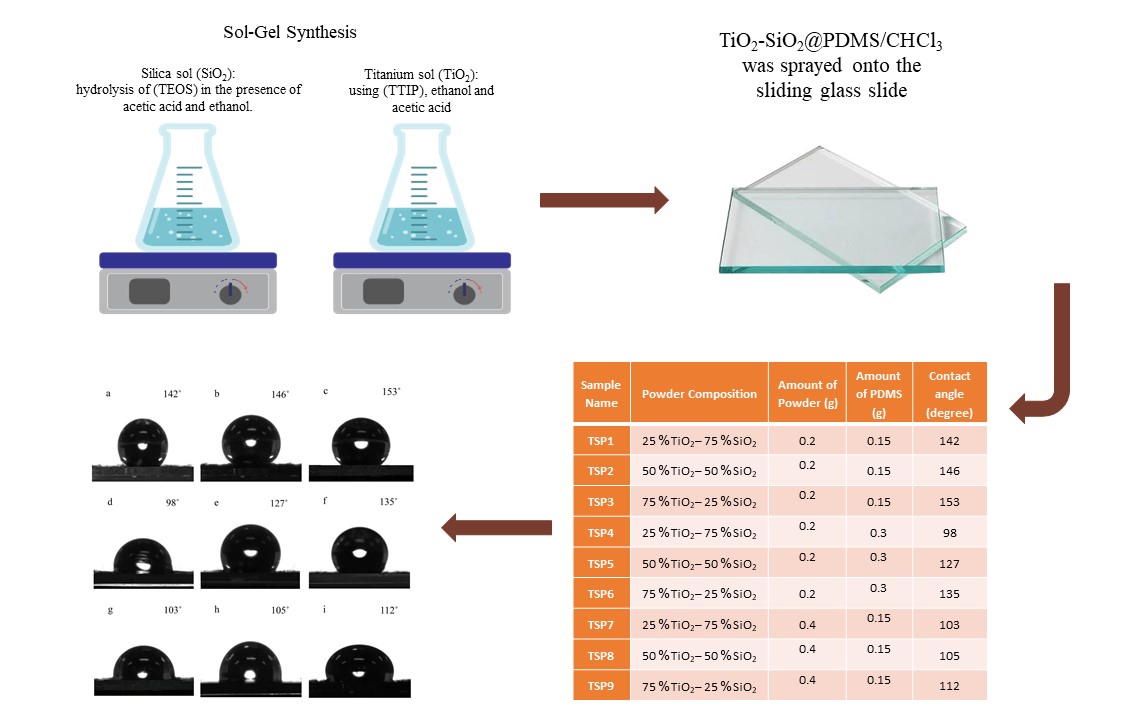

Sazvar A, Alavi S M S, Sarpoolaky H. Effect of Chemical Composition on Microstructure and Hydrophobic Properties of SiO2-TiO2@PDMS Coating. IJMSE 2023; 20 (2) :1-11

URL: http://ijmse.iust.ac.ir/article-1-3114-en.html

URL: http://ijmse.iust.ac.ir/article-1-3114-en.html

Abstract: (10392 Views)

We report a simple and practical approach for the easy production of superhydrophobic coatings based on TiO2-SiO2@PDMS. In this study, we used tetraethylorthosilicate (TEOS) and titanium tetraisopropoxide (TTIP) as a precursor for the sol-gel synthesis of SiO2 and TiO2, respectively. Afterward, the surface of nanoparticles was modified by 1,1,1,3,3,3-hexamethyldisilazane (HMDS) before being combined with polydimethylsiloxane (PDMS). The hydrophobic property of coatings was evaluated by static contact angle measurements. The phase composition and structural evolution of the coatings were examined by X-ray diffraction (XRD), and Fourier transform infrared spectroscopy (FTIR) analysis. It was shown that changing the weight ratio of the solution composition of the coating can affect the hydrophobicity of the surface. The best sample has shown a superhydrophobic property with a 153˚ contact angle which contained (75%TiO2-25%SiO2) and PDMS at a weight ratio of 1:1. Moreover, the results showed that the superhydrophobic coating retains its hydrophobic properties up to a temperature of 450 ˚C, and at higher temperatures, it converts to a super hydrophilic with a water contact angle close to 0 ˚. The SiO2-TiO2@PDMS coating degrades methylene blue by about 55% and was shown to be capable of photocatalytically decomposing organic pollutants.

Type of Study: Research Paper |

Subject:

Coatings and Corrosion Phenomenon

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |