Sat, Jul 19, 2025

[Archive]

Volume 16, Issue 4 (December 2019)

IJMSE 2019, 16(4): 10-19 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Aydın H. Effect of the La2O3 Addition on Thermal, Microstructure and Mechanical Properties of Mullite–Zirconia Composites. IJMSE 2019; 16 (4) :10-19

URL: http://ijmse.iust.ac.ir/article-1-1297-en.html

URL: http://ijmse.iust.ac.ir/article-1-1297-en.html

Abstract: (21867 Views)

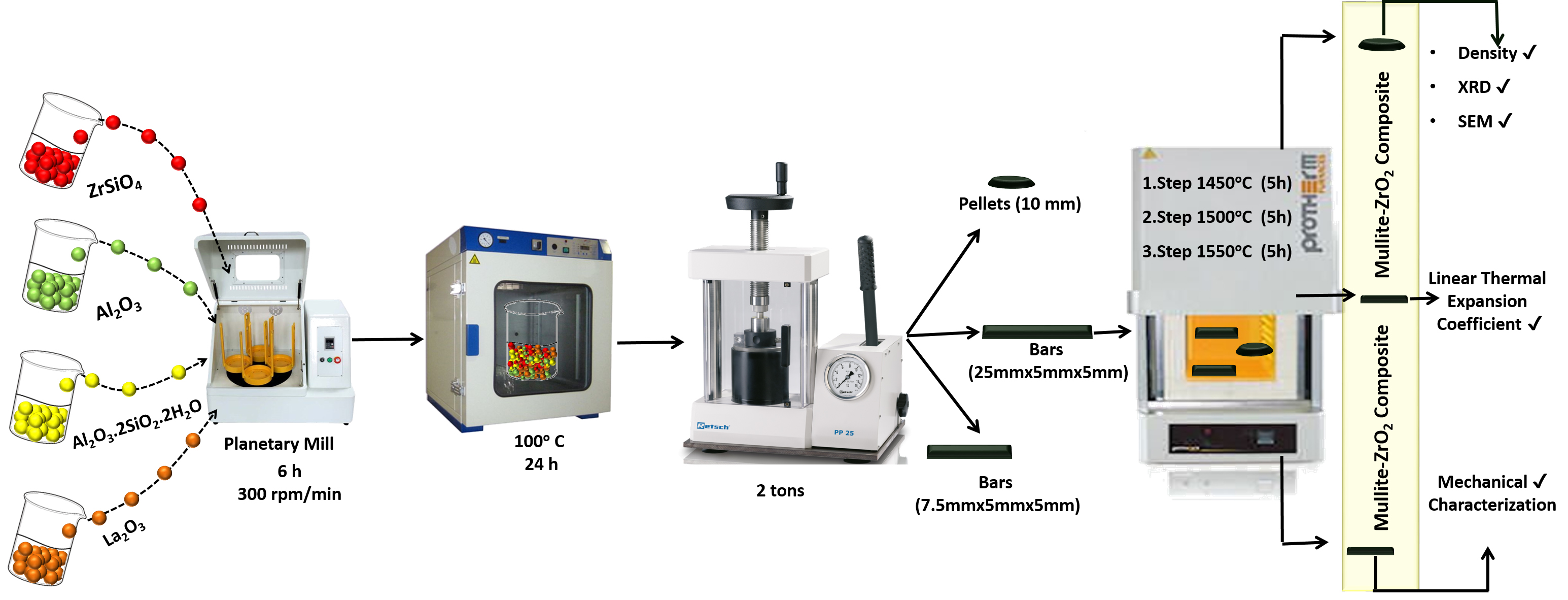

Mullite–zirconia composites were prepared using lanthanum oxide (La2O3) additive which three different mole ratio by the reaction sintering (RS) route of alumina, kaolinite and zircon. Starting materials were planetary milled, shaped into pellets and bars and sintered in the temperature range of 1450–1550 0C with 5 h soaking at peak temperature. In this work, the mullite-zirconia composites were characterized by thermal expansion coefficient, physical, microstructures and mechanical properties. The XRD method were employed for determining the crystalline phase composition of these composites. Microstructure of the composites was examined by SEM. ZrO2 takes part in both the intergranular as well as intragranular positions. However, intragranular zirconias are much smaller compared to intergranular zirconias.

Keywords: Mullite-zirconia composites, thermal expansion coefficient, reaction sintering, mechanical properties

Type of Study: Research Paper |

Subject:

Ceramic Materials and Engineering

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |